Hex

Year: Spring 2016

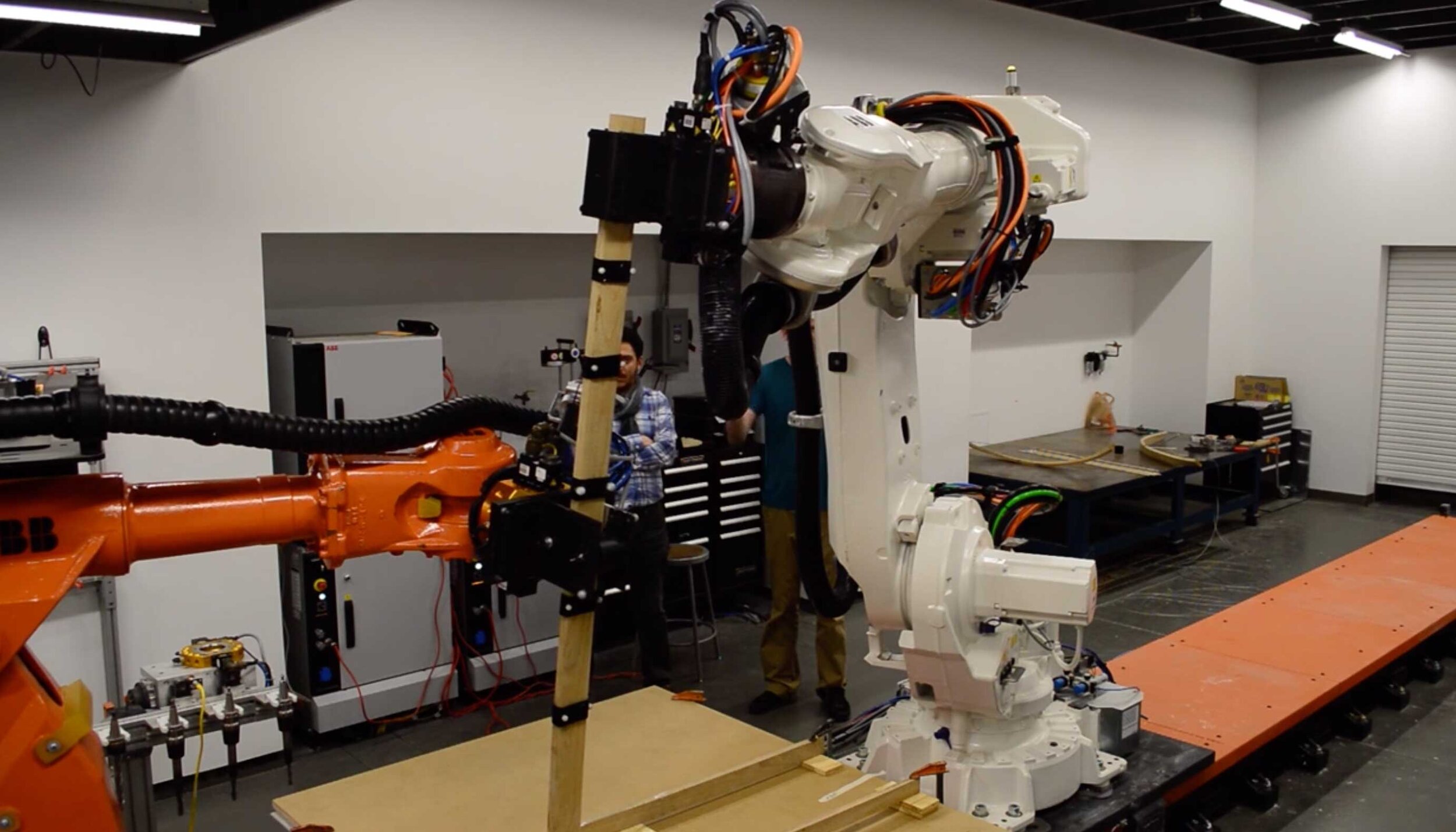

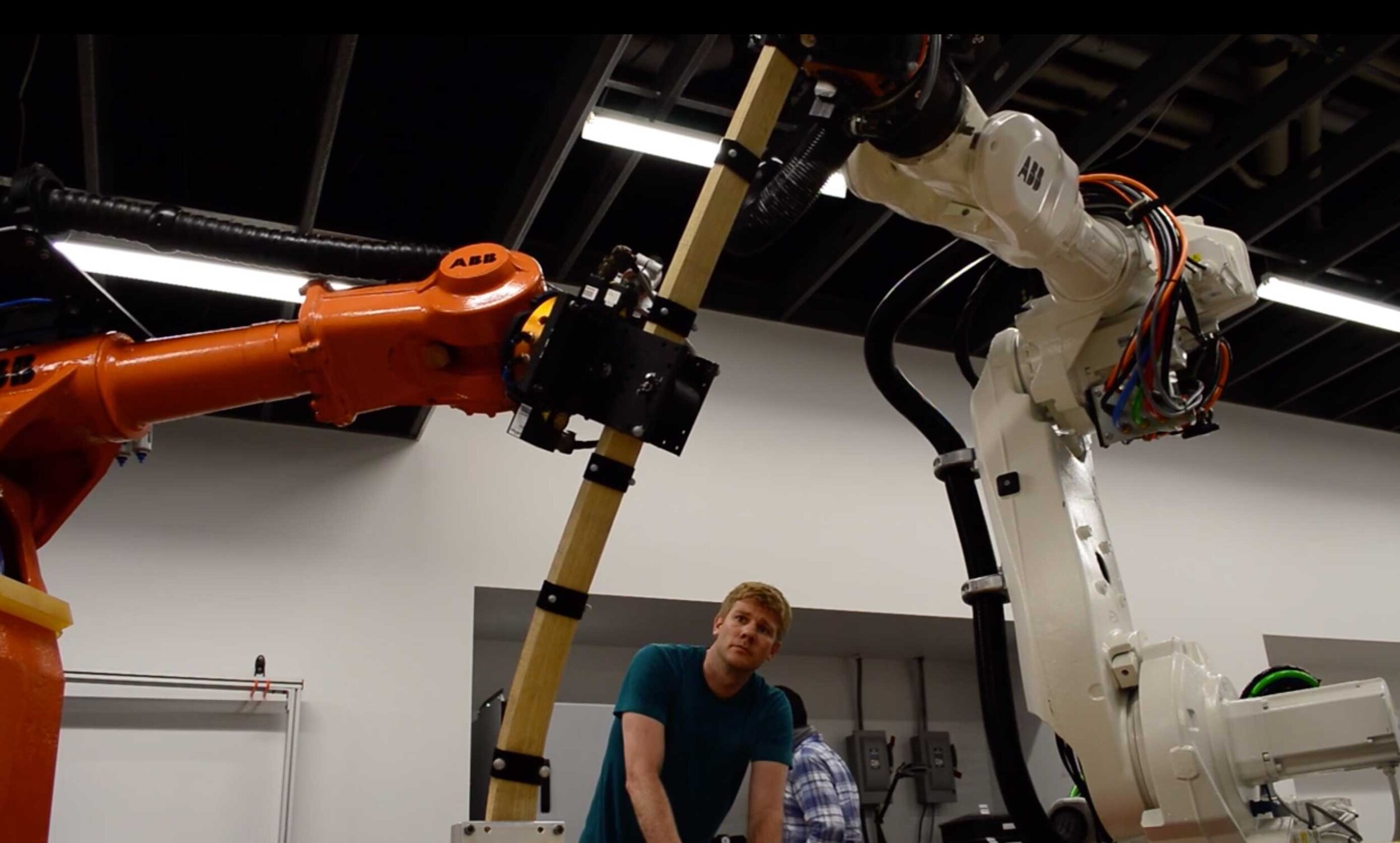

Project: Robotic Fabrication

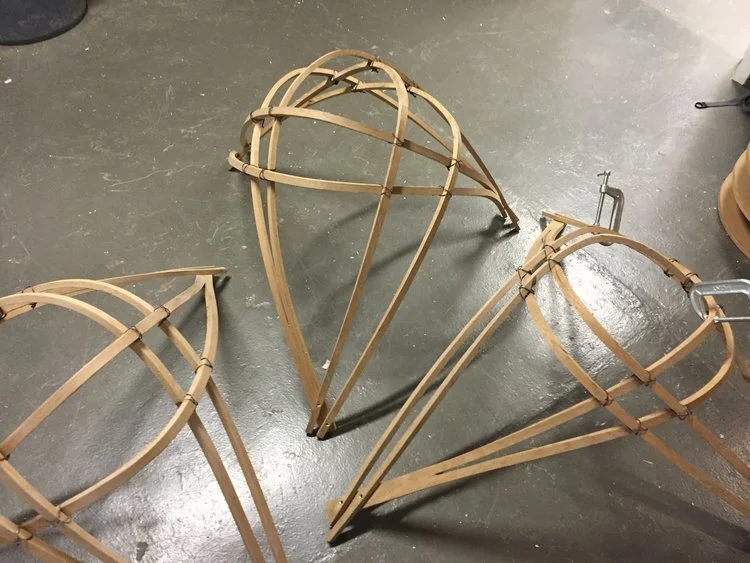

Hex is a fabricated full-scale modular prototype of a larger designed truss system intended for a spanned roof support. It explores traditional wood construction with emerging robotically assisted technologies of fabrication.

// Exhibited: l

* Carnegie Mellon University - College of Fine Arts.

Concept

Contemporary architectural practice is a constant state of techno-flux. The means and methods of contemporary architectural production face mounting ecological imperatives.

Hex explores the resourcefulness of wood construction through robotically assisted fabrication. In particular, we investigated robotic steam bending, where a robot’s ability to shape custom framing members and assemble unique parts, is leveraged to construct complex material arrays.

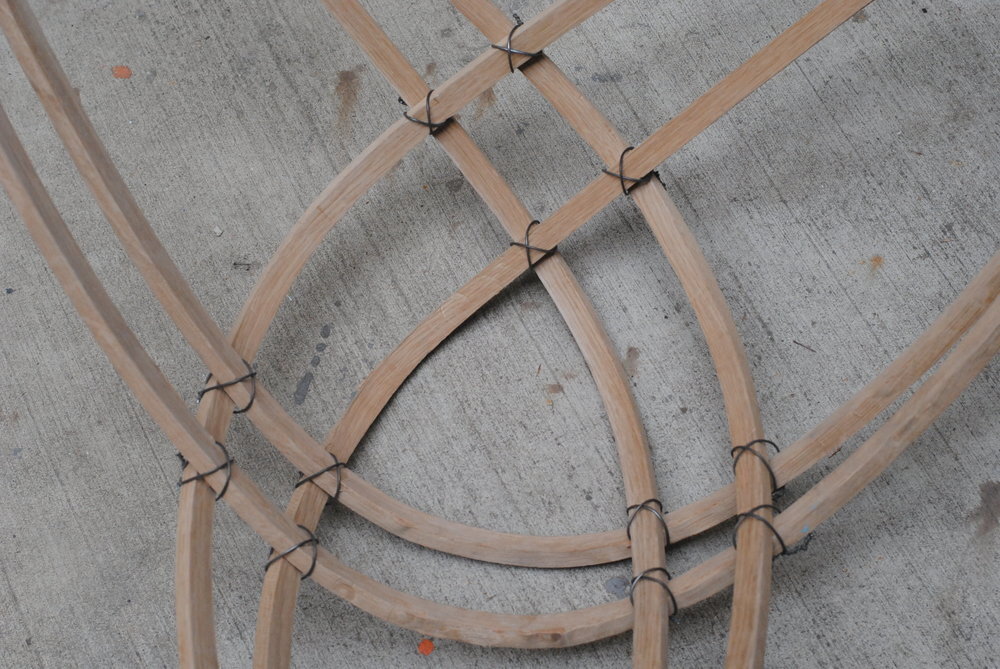

Hex was inspired by the act of "weaving" fabric. We challenged ourselves with the task of interlacing wood in the same way.

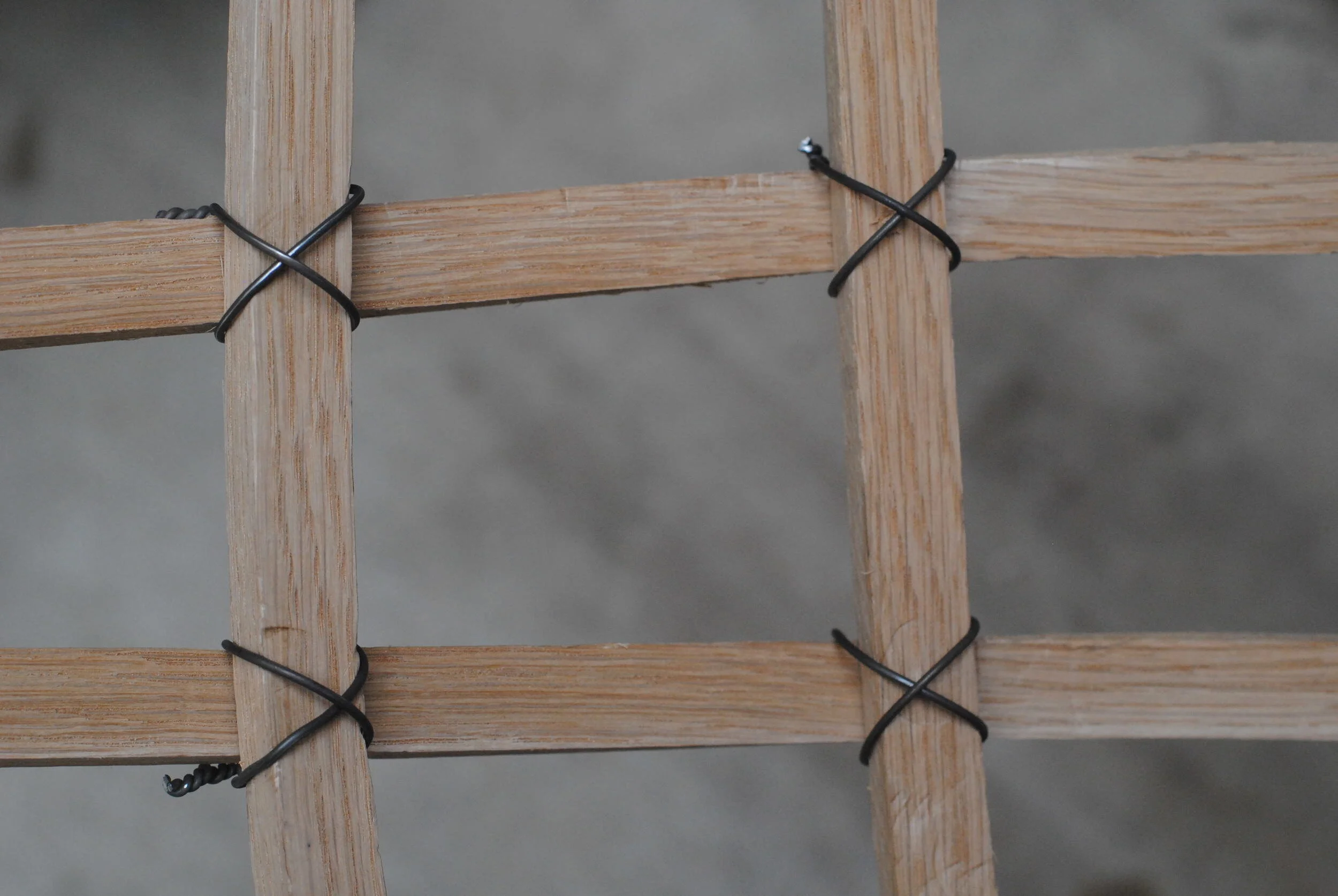

We found the optimal shape for our basic unit to be a piece with a slit that stretches 2/3 of the way across the wood. From there, we started weaving the unit to create a final 3-piece system that acted as our module.

Our Process - Robotic Steam Bending?

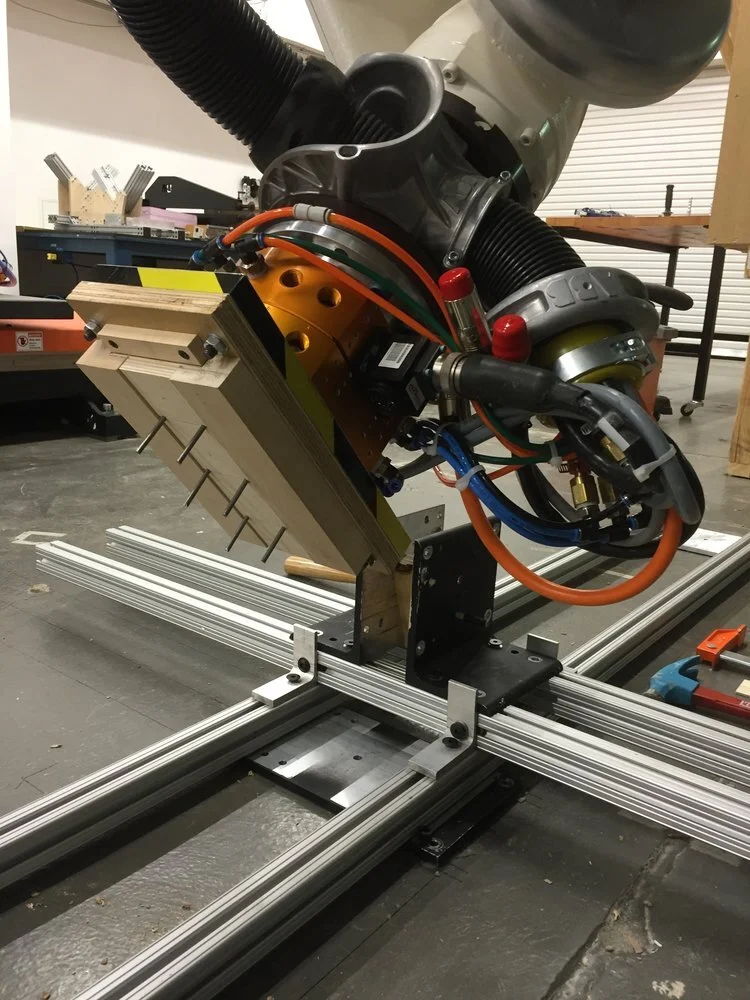

Tools: Wood working, ABB industrial robotic arm, RAPID programming, RobotStudio simulation, Rhino, and Grasshopper scripting

After constructing a prototype of Hex— we began studying the two phases of the steam bending process:

Phase I - Creating a mechanism + a claw for the robot to hold and twist our wood into desired shape

Phase II - Creating a mechanism to fasten the bent wood in order for it to dry in that position

Using Rhino and Grasshopper, I re-created Hex’s geometry digitally and programmed the robot's motions procedurally with RobotStudio.

It was definitely a human+robot team effort 🤖